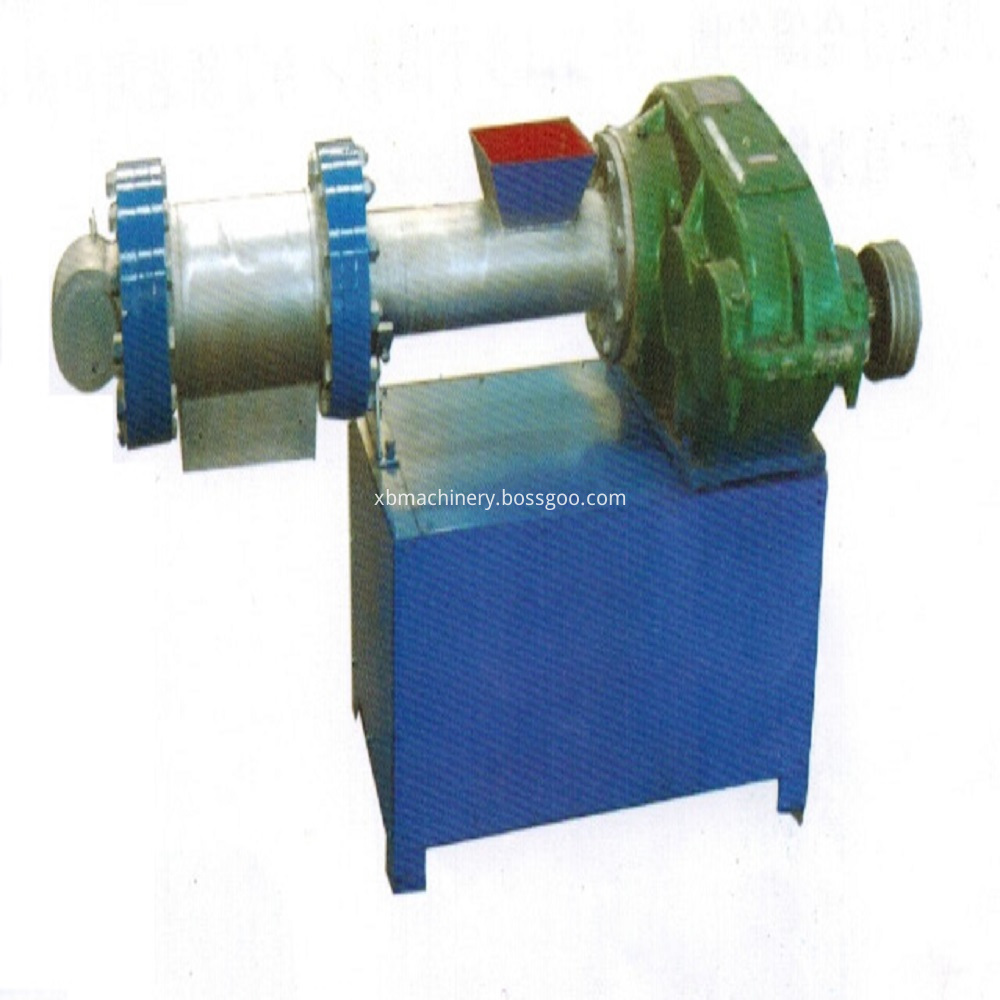

waste plastic recycling extruder machine

Basic Info

Model No.: XB-95/39

Product Description

(1) Screw: It is the most important part of the extruder. It is directly related to the application range and productivity of the extruder. It is made of high strength and corrosion resistant alloy steel.

(2) Barrel: It is a metal cylinder, which is generally made of alloy steel with high heat resistance, high compressive strength, strong wear resistance and corrosion resistance or composite steel pipe lined with alloy steel. The barrel is matched with the screw to achieve pulverization, softening, melting, plasticizing, venting and compacting of the plastic, and continuously and uniformly conveying the rubber to the molding system. The length of the general barrel is 15 to 30 times its diameter, so that the plastic is fully heated and fully plasticized.

(3) Hopper: The bottom of the hopper is equipped with a cutting device to adjust and cut the flow. The side of the hopper is equipped with a sight hole and a calibration metering device.

(4) Handpiece and mold: The machine head is composed of an alloy steel inner sleeve and a carbon steel jacket, and a molding die is arranged in the machine head. The function of the machine head is to transform the rotating plastic melt into a parallel linear motion, which is evenly and smoothly introduced into the mold sleeve and imparts the necessary molding pressure to the plastic. The plastic is plasticized and compacted in the barrel, and the porous filter plate flows into the head forming mold through the neck of the head through a certain flow path, and the core mold sleeve is properly matched to form an annular gap with a decreasing cross section, so that the plastic melt is in the A continuous dense tubular coating is formed around the core. In order to ensure the plastic flow path in the machine head is reasonable, and eliminate the dead angle of the accumulated plastic, a shunt sleeve is often placed. In order to eliminate the pressure fluctuation during plastic extrusion, a pressure equalizing ring is also provided. A mold correction and adjustment device is also mounted on the handpiece to facilitate adjustment and correction of the concentricity of the core and the mold sleeve. 2. Transmission system The function of the transmission system is to drive the screw. The torque and speed required by the supply screw during the extrusion process are usually composed of a motor, a reducer and a bearing.

company Describes

Shandong Qufu Xingbang Heavy Industry Equipment Co., Ltd. will build a science and technology leading enterprise integrating R&D, manufacturing and installation, and international trade. The main products developed and manufactured include building materials equipment: automatic glass magnesium fireproof board production line, large-scale multi-functional wall board exterior wall insulation board production line, environmental fireproof door core board production line, new energy straw board making machine, fully automatic cutting saw; woodworking machinery : Automatic veneer machine, sticker machine, automatic curing machine, UV light curing machine, hot pressing veneer machine, vacuum machine, cold press machine, universal coating machine and other products, all of which have passed the relevant national departments The technical appraisal and recognition has enjoyed a good reputation in the market and has been well received by customers. The company's products are sold to all parts of the country and some surrounding countries and have achieved high economic and social benefits.

Building Material Making Machinery

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

Glass Magnesium Fire Board Decorating Plate Production Line

Plastic Extrusion And Recovery Equipment

Plastic Extruder Machine

Plastic Pelletizing Recycling Machine

Sheet Plate Board Extrusion Line

Plastic Washing Recycling Machine

Product Categories : Plastic Extrusion And Recovery Equipment > Plastic Extruder Machine