Oilseed Srew Rapeseed Peanut Oil Expeller Machinery

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA,CIP |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 10 Days |

| Packaging: | Nude |

|---|---|

| Productivity: | 100sets per month |

| Brand: | Yongsheng |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Hebei |

| Supply Ability: | 500sets |

| Certificate: | ISO |

| HS Code: | 8479200000 |

| Port: | Tianjin,Qingdao,Lianyungang |

Basic Info

Model No.: 200A-3

Click on the follow link to find out more information: https://www.oilpresschina.com/oil-press/

Company Info

- Company Name: Hebei Huipin Machinery Co.,LTD

- Representative: Wei Xie

- Product/Service: Oil Press , Oil Expeller , Cooking Oil Production Line , Oil Pressing Machine , Cooking Oil Extraction Machine , Edible Oil Processing Machine

- Capital (Million US $): 3,000,000RMB

- Year Established: 2019

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 20

- No. of R&D Staff: 21 -30 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: Beituan Village, DingZhou City,Hebei Province,China

- Contact Person: Ms. Candy Wang

- Tel: 86-0312-2727088

Premium Related Products

Other Products

Hot Products

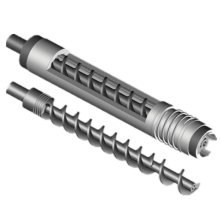

Screw and Barrel for Rubber Extruder MachineInjection Molding Screw Barrel PP Injection Screw BarrelSegmented Barrel Sectional Barrel Plastic Extruder BarrelMulti Screw for Extruder and Planetary Screw BarrelSheet Extruder Single Screw Barrel / Single Screw Barrel for Extruder (Dia15-300mm)Feed Screws Extruder ScrewsDouble Screw and Barrel/Parallel Twin Screw and BarrelAccessories of Injection Screw/Injection Machine Accessoriesfeed housing with 38CrMoAlA base steel for barrelbimetallic screw with Ni60 from KENNAMETAL STELLITE38CrMoAlA screw barrel for injection molding machineinjection mould machine screw barrel with nitrided and bimetallic treatmentPVC plastic machine screw barrel/Extruder Conical Twin Screw Barrelparallel twin screw barrel for plastic extruder machine with competitive pricesingle barrel for extruder/high quality barrel for plastic extruder machineextruder rubber screw for pvc wire extrusion machine